In the USA, scaffold-related accidents are a significant concern in the construction industry, with over 60 scaffolding-related deaths per year, according to OSHA reports. In the UK 50% of all fatalities in the construction industry are due to falls from a height.

Implementing proper safety measures to reduce scaffold-related accidents and training workers on scaffold safety can help prevent these accidents. Accident prevention is crucial in reducing the risk of injuries and fatalities on construction sites. By following workplace safety tips and injury prevention strategies, employers can ensure a safe working environment for their employees.

According to OSHA, scaffolding accidents often occur due to negligence by construction companies, scaffold installers, or manufacturers. Employers must provide adequate fall prevention measures, including safety netting and guardrails, for scaffolds higher than 10 feet. Regular inspections of scaffolds are also mandated before each shift to ensure the structural integrity of the scaffolding. By prioritising accident prevention and implementing effective safety measures, construction companies can reduce the risk of scaffolding accidents and promote a safety culture within the workforce.

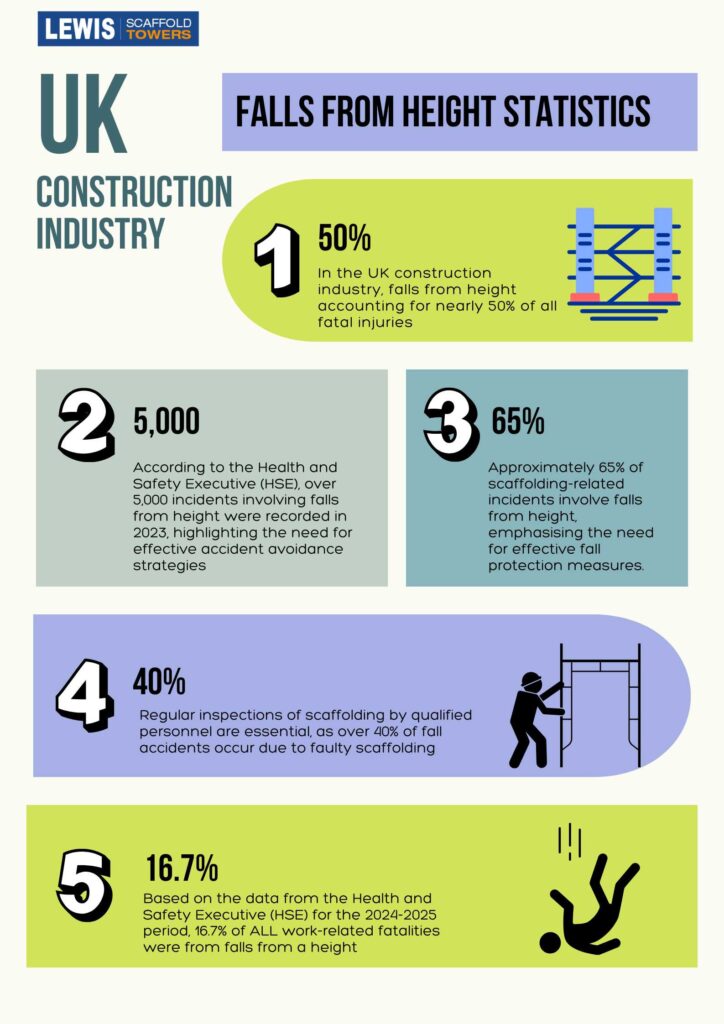

Below you can quickly check some of the top statistics when it comes to scaffold-related accidents and other falls from a height in the UK.

Understanding the Impact of Scaffold-Related Accidents in UK Construction

The UK construction industry faces significant risks from scaffold-related incidents, with falls from height accounting for nearly 50% of all fatal injuries. Safety measures are crucial in preventing such accidents, and hazard identification plays a vital role in this process. According to the Health and Safety Executive (HSE), over 5,000 incidents involving falls from height were recorded in 2023, highlighting the need for effective accident avoidance strategies.

Some key statistics on scaffold-related incidents in the UK include:

- Falls from height, including scaffolding accidents, account for nearly 50% of all fatal injuries in the UK construction industry.

- Falls from a height accounted for 16.67% of fatalities from ALL industries.

- Approximately 65% of scaffolding-related incidents involve falls from height, emphasizing the need for effective fall protection measures.

- Regular inspections of scaffolding by qualified personnel are essential, as over 40% of fall accidents occur due to faulty scaffolding.

Implementing safety measures and conducting thorough hazard identification can significantly reduce the likelihood of accidents on construction sites involving scaffolding. By prioritizing accident avoidance, the construction industry can minimize the risks associated with scaffold-related incidents and create a safer working environment.

Key to reducing scaffold-related accidents is the implementation of effective safety protocols and procedures. This includes providing comprehensive training programs for workers, conducting regular inspections, and maintaining clear and organized work platforms. By following these workplace safety tips and injury prevention strategies, construction companies can reduce the risk of accidents and promote a safe working environment.

Essential Components of Scaffold Safety Management

Effective scaffold safety management is crucial in preventing accidents and ensuring the well-being of workers on construction sites. By implementing safety protocols and providing safety training techniques, employers can significantly reduce the risk of preventable accidents. Regular inspections and maintenance are also vital in identifying potential hazards and taking corrective action.

A comprehensive safety plan should include the following key elements:

- Regular inspections and maintenance of scaffolds

- Provision of safety training for workers

- Implementation of safety protocols and procedures

- Use of personal protective equipment (PPE)

By prioritizing scaffold safety management, employers can create a safe working environment and reduce the risk of accidents. This not only protects workers but also helps to prevent costly downtime and damage to equipment.

According to statistics, regular inspections and maintenance can mitigate risks, with over 70% of accidents happening during the first week of scaffold use if not properly inspected. Additionally, using trained personnel for scaffold inspection reduces the likelihood of accidents by 45%, emphasizing the importance of training and supervision.

| Statistic | Percentage |

|---|---|

| Accidents prevented with regular inspections | 70% |

| Reduction in accidents with trained personnel | 45% |

UK Regulatory Framework and Compliance Requirements

The UK regulatory framework plays a crucial role in ensuring workplace safety tips are implemented and injury prevention strategies are in place. The Health and Safety at Work etc Act 1974 requires employers to plan, organise, control, monitor, and review health and safety arrangements. This includes implementing safety measures to prevent accidents and ensuring compliance with relevant regulations.

Employers must also comply with the Reporting of Injuries, Diseases, and Dangerous Occurrences Regulations 2013 (RIDDOR 2013), which mandates the reporting of fatalities, specified injuries, and dangerous occurrences to the Health and Safety Executive (HSE). This helps to identify areas for improvement and implement effective safety measures to prevent future incidents.

In addition to these regulations, employers must also adhere to the Work at Height Regulations 2005, which provides guidance on safety measures for working at height. By following these regulations and implementing effective injury prevention strategies, employers can reduce the risk of accidents and ensure a safe working environment for their employees.

Some key safety measures that employers can implement include:

- Conducting regular risk assessments to identify potential hazards

- Providing training and equipment to employees to ensure they can work safely

- Establishing clear procedures for reporting incidents and accidents

By prioritizing workplace safety tips and implementing effective safety measures, employers can reduce the risk of accidents and create a safe and healthy work environment for their employees.

Effective Accident Prevention Strategies for Scaffold Operations

Accident avoidance is a critical aspect of scaffold operations, and employers must implement safety protocols to prevent preventable accidents. According to OSHA, millions of construction industry workers perform work on scaffolds annually, and it is essential to ensure their safety.

The implementation of control measures, such as regular inspections and maintenance, is crucial in preventing accidents. High-strength steel is commonly used for scaffolding due to its robustness, and galvanized steel is preferred for corrosion resistance, which extends the lifespan of scaffolds.

A comprehensive safety plan must include risk assessment procedures, implementation of control measures, and emergency response planning. The following are key elements of an effective safety plan:

- Risk assessment procedures to identify potential hazards

- Implementation of control measures, such as regular inspections and maintenance

- Emergency response planning, including training and equipment

By implementing these safety protocols, employers can reduce the risk of preventable accidents and ensure a safe working environment for their employees. Regular inspections and maintenance are essential in identifying signs of wear, damage, or corrosion in scaffolding systems, and materials should only be sourced from reputable suppliers.

OSHA standards relevant to quality materials are denoted under 29 CFR 1926.451(c)(2), emphasizing the importance of meeting established strength requirements. By following these guidelines and implementing effective accident prevention strategies, employers can minimize the risk of accidents and ensure a safe working environment for their employees.

Professional Training and Competency Requirements

Ensuring the competence of personnel is crucial in preventing scaffold-related accidents. According to the Health and Safety Executive guidelines, competence assurance should be directly linked to key responsibilities and tasks identified in risk assessments. This involves providing workers with safety training techniques and workplace safety tips to equip them with the necessary skills to perform their tasks safely.

A well-structured training program should include both theoretical and practical components, with a focus on injury prevention strategies. This can be achieved through a combination of formal training, on-the-job training, and periodic assessments to ensure that workers are competent to carry out their tasks. The importance of competency assurance is highlighted by the fact that inadequate management of competence has contributed to many major accidents in the construction industry.

Some key aspects of a competency assurance system include:

- Conducting periodic assessments to ensure ongoing compliance with safety standards

- Directly linking competence to key responsibilities and tasks

- Providing structured on-the-job training

Key Takeaways

- Implementing proper safety measures can help prevent scaffold-related accidents

- Training workers on scaffold safety is crucial in reducing the risk of injuries and fatalities

- Employers must provide adequate fall prevention measures, including safety netting and guardrails

- Regular inspections of scaffolds are mandated before each shift to ensure structural integrity

- Comprehensive training programs can reduce the risk of accidental injuries and promote safety culture

- Workers have the right to refuse unsafe working conditions without risking employment

By implementing a comprehensive competency assurance system, employers can reduce the risk of scaffold-related accidents and ensure a safer working environment for their employees. This, in turn, can lead to improved productivity, reduced downtime, and a better reputation for the company.

| Competency Aspect | Description |

|---|---|

| Training and Assessment | Providing workers with the necessary training and assessing their competence to perform tasks safely |

| Supervision and Oversight | Ensuring that workers are supervised and overseen by competent personnel to prevent accidents |

| Continuous Improvement | Continuously reviewing and improving the competency assurance system to ensure it remains effective |

Regular Inspection and Maintenance Protocols

Regular inspections and maintenance are crucial in preventing accidents and ensuring the safety of workers and equipment. By implementing safety measures such as daily checks and documentation, companies can identify potential hazards and take steps to avoid accidents. Hazard identification techniques, such as risk assessments and job safety analyses, can help identify potential hazards and develop strategies to mitigate them.

Periodic professional assessments are also essential in ensuring that equipment is properly maintained and that any potential issues are addressed before they become major problems. This can include accident avoidance measures such as regular cleaning and maintenance of equipment, as well as training staff on maintenance procedures and hazard management. Weather-related considerations, such as extreme temperatures or weather conditions, can also impact safety measures and should be taken into account when developing maintenance protocols.

Some key benefits of regular inspections and maintenance include:

- Reduced likelihood of accidents and injuries

- Extended lifespan of equipment

- Improved productivity and efficiency

- Enhanced compliance with safety regulations

By investing in preventive maintenance and implementing regular inspection and maintenance protocols, companies can enhance the useful life of their assets, support a productive work environment, and most importantly, ensure the safety of their workers.

Personal Protective Equipment and Safety Equipment Standards

The importance of personal protective equipment (PPE) and safety equipment standards cannot be overstated, particularly in the construction industry where safety protocols are crucial in preventing preventable accidents. According to the Personal Protective Equipment at Work (Amendment) Regulations 2022, employers are required to provide suitable PPE free of charge to both employees and limb (b) workers.

A study by the National Safety Council found that wearing appropriate PPE reduces the risk of injury by up to 80%. Furthermore, proper use of head protection can reduce head injuries by approximately 35%. The use of safety glasses in environments with flying debris can decrease the risk of eye injuries by 90%. It is essential for employers to provide safety training techniques to ensure that workers are aware of the importance of PPE and how to use it correctly.

Some key statistics highlighting the importance of PPE in construction include:

- 25% of construction site accidents are linked to exposure to harmful substances

- 40% of construction-related fatalities are due to falls, making fall protection equipment critical

- 80% of workers do not wear adequate PPE consistently when required, particularly on scaffolds

By implementing a strong PPE training program and ensuring that workers are aware of the importance of safety protocols, employers can reduce workplace injuries by 60%. It is crucial for contractors to provide PPE and ensure that workers receive adequate training on its use to prevent preventable accidents and promote a culture of safety.

| PPE Type | Importance | Reduction in Injuries |

|---|---|---|

| Head Protection | Essential for preventing head injuries | Up to 85% |

| Safety Glasses | Crucial for preventing eye injuries | Up to 90% |

| Fall Protection Equipment | Vital for preventing falls | Up to 96% |

Communication and Safety Culture Development

Effective communication is crucial in preventing scaffold-related accidents. By implementing workplace safety tips and injury prevention strategies, organizations can significantly reduce the risk of accidents. A strong safety culture is essential in promoting a safe working environment, where workers feel empowered to report potential hazards and near-miss incidents without fear of reprisal.

Regular toolbox talks and safety briefings are vital in maintaining open communication channels. These sessions provide an opportunity for workers to discuss safety concerns, share experiences, and receive updates on new safety measures. By fostering a culture of transparency and accountability, organizations can encourage worker engagement and participation in safety-related discussions.

A well-structured reporting system, coupled with a feedback loop, enables organizations to respond promptly to safety concerns and near-miss incidents. This proactive approach helps to identify potential hazards, implement corrective actions, and evaluate the effectiveness of safety measures. By prioritizing communication and safety culture development, organizations can reduce scaffold-related accidents, promote a safe working environment, and minimize the risk of injuries and fatalities.

| Strategy | Benefits |

|---|---|

| Regular Toolbox Talks | Improved communication, increased worker engagement |

| Implementation of Safety Measures | Reduced risk of accidents, improved safety culture |

| Reporting Systems and Feedback Loops | Prompt response to safety concerns, improved incident reporting |

Conclusion: Building a Sustainable Safety Framework

As we conclude this comprehensive exploration of scaffold safety, it’s clear that creating a sustainable safety framework is essential to preventing and safeguarding construction workers. By implementing robust and prioritising , employers can foster a culture of safety that empowers workers and minimises the risk of tragic incidents.

The key lies in a holistic approach that encompasses thorough training, rigorous inspections, and the adoption of industry-leading best practices. Through collaborative efforts and a steadfast commitment to worker welfare, construction companies can build a resilient safety infrastructure that withstands the challenges of the modern worksite.

By embracing this proactive mindset, we can reshape the landscape of construction safety, paving the way for a future where every worker returns home safely at the end of the day. As we move forward, let us remain vigilant, adaptable, and unwavering in our pursuit of a truly secure and sustainable construction environment.

FAQ

What are the common causes of scaffolding accidents on construction sites?

Scaffolding accidents on construction sites can be caused by a variety of factors, including improper installation, lack of proper inspections, the use of defective equipment, and inadequate worker training on scaffold safety.

Why is it important to implement proper safety measures for scaffold operations?

Implementing proper safety measures for scaffold operations is crucial to prevent accidents and reduce the risk of injuries or fatalities on construction sites. This includes regular inspections, maintenance, and ensuring that workers are properly trained on scaffold safety protocols.

What is the current state of scaffold-related incidents in UK construction?

Scaffold-related incidents continue to be a significant concern in the UK construction industry, with a large number of accidents reported each year. These incidents can result in substantial financial and human costs, highlighting the need for a comprehensive approach to scaffold safety management.

What are the key components of an effective scaffold safety management plan?

An effective scaffold safety management plan should include regular inspections, maintenance protocols, comprehensive safety training for workers, and the implementation of control measures to mitigate identified risks. Employers have a legal responsibility to ensure a safe working environment for their workers.

What are the legal requirements and regulatory framework for scaffold safety in the UK?

The Work at Height Regulations 2005 and HSE guidelines and standards provide the regulatory framework for scaffold safety in the UK. Employers must comply with these regulations to ensure the safety of their workers and prevent scaffold-related accidents.

What are the essential accident prevention strategies for scaffold operations?

Effective accident prevention strategies for scaffold operations include thorough risk assessment procedures, the implementation of appropriate control measures, and comprehensive emergency response planning. Employers must take a proactive approach to ensuring the safety of their workers.

Why is professional training and competency important for scaffold safety?

Professional training and competency assessments are crucial for ensuring that workers are equipped with the necessary knowledge and skills to safely operate and work on scaffolds. Employers have a responsibility to provide comprehensive training and ensure that their workers are properly certified.

What are the key elements of a scaffold inspection and maintenance protocol?

Scaffold inspection and maintenance protocols should include daily checks, periodic professional assessments, and considerations for weather-related factors. Proper documentation and identification of hazards are essential to prevent accidents and ensure the ongoing safety of the scaffold structure.

What personal protective equipment and safety equipment standards are required for scaffold operations?

Employers must provide their workers with the appropriate personal protective equipment and ensure that all safety equipment meets the necessary standards. This is a critical component of a comprehensive scaffold safety plan to protect workers from potential harm.

How can communication and safety culture development contribute to scaffold safety?

Effective communication, through tools like toolbox talks and safety briefings, as well as the development of a strong safety culture, can significantly contribute to the overall safety of scaffold operations. Reporting systems, feedback loops, and worker engagement strategies are all important elements in fostering a safety-conscious environment.