Falls from height remain a significant concern in the UK’s workplace safety landscape. In the 2023/24 period, 50 workers lost their lives due to falls from height, marking a notable increase from 41 fatalities in the previous year. This rise underscores the critical importance of stringent safety measures and adherence to regulations when working at elevated positions.

For this reason, we have produced this Industrial Scaffold Towers Safety Refresher, as well as this short video about Scaffold Tower Safety Tips.

Industrial Scaffold Towers Safety Refresher

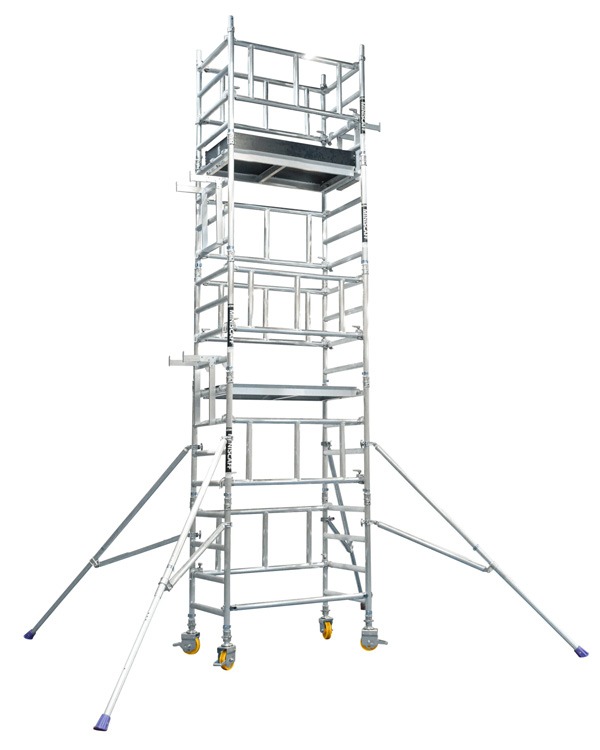

Ensuring the safety of workers is paramount when working at height, and a crucial aspect of this is the proper use and maintenance of industrial scaffold towers. In the United Kingdom, scaffolds not assembled to a standard configuration must be designed through bespoke calculations by a competent person to ensure safety, as per the Work at Height Regulations 2005. A safety checklist is essential to prevent falls and accidents, and it is vital to conduct regular workplace safety inspections and safety audits to identify potential hazards.

This industrial scaffold towers safety refresher includes this easy to use infographic below to highlight some of the basics.

Industrial Scaffold Tower Safety Infographic (Download as PDF)

A properly planned scaffold should consider variables like the maximum number of personnel using it at one time and maximum working loads imposed. Scaffolds should be assumed to have a general purpose maximum load capacity of 2 kN/m², unless specified otherwise by the provider. Guard rails must be positioned at least 950 mm above any edge from which individuals could fall, and the gap between intermediate guard rails should not exceed 470 mm to prevent falls or material spillage. Regular safety audits and workplace safety inspections can help identify potential risks and prevent accidents.

Industrial Scaffold Towers Key Takeaways

- Conduct regular workplace safety inspections to identify potential hazards

- Ensure scaffold towers are designed and assembled by competent persons

- Conduct regular safety audits to prevent accidents and ensure compliance with regulations

- Position guard rails at least 950 mm above any edge from which individuals could fall

- Ensure the gap between intermediate guard rails does not exceed 470 mm

- Assume a general purpose maximum load capacity of 2 kN/m², unless specified otherwise by the provider

By following these guidelines and conducting regular safety checklists, workplace safety inspections, and safety audits, we can help prevent accidents and ensure the safety of workers using industrial scaffold towers.

Understanding Industrial Scaffold Towers Safety Fundamentals

Industrial scaffold towers are a crucial component in various industries, providing height access for tasks. However, their use also poses significant risks if not managed properly. To ensure safety, it is essential to understand the fundamentals of industrial scaffold tower safety, including key components, legal requirements, and risk assessment basics.

Key Components of Scaffold Tower Safety

A stable and level surface is essential for scaffold stability; an uneven foundation can lead to accidents. Overloading a scaffold beyond its load capacity can cause structural failure, resulting in serious accidents. Scaffolding tags provide essential inspection status and load capacity information; usage of scaffolding with a green tag is recommended for safety.

Legal Requirements in the UK

In the UK, employers and self-employed contractors must comply with the Work at Height Regulations 2005. This includes conducting regular risk assessments and implementing control measures to minimize the risk of falls. Safety procedures and safety measures must be in place to ensure a safe working environment.

Risk Assessment Basics

The law requires that employers and self-employed contractors assess the risk from work at height and go on to organise and plan the work so it is carried out safely.

HSE UK

Risk assessment is a critical component of scaffold tower safety. It involves identifying potential hazards and implementing control measures to minimise the risk of accidents. This includes assessing the scaffold’s load capacity, ensuring a stable and level surface, and doing everything according to the legal regulations.

By understanding the fundamentals of industrial scaffold tower safety, employers and self-employed contractors can minimise the risk of accidents and ensure a safe working environment. This includes implementing safety procedures and safety measures, complying with regulations, and conducting regular risk assessments.

Pre-Use Safety Checklist for Scaffold Towers

Before using a scaffold tower, it is essential to conduct a thorough safety assessment to ensure the tower is stable and secure. This includes checking the manufacturer’s assembly guidelines, guardrails, mid-rails, and toe boards. A pre-use safety checklist can help identify potential hazards and prevent accidents.

According to the Health and Safety Executive (HSE), 14 people suffered a non-fatal fall from height in the workplace every day in 2019/20. To minimize the risk of falls, scaffold towers must be inspected following assembly and then at suitable regular intervals, with an inspection required every 7 days if the working platform has a potential fall height of 2 metres or more.

The following safety guidelines should be included in the pre-use safety checklist:

- Check the scaffold tower’s stability and levelness

- Verify that all guardrails, mid-rails, and toe boards are in place and secure

- Inspect the tower’s components, including the frame, platforms, and ladders

- Check for any damage or wear and tear on the tower’s components

- Ensure that the tower is properly anchored to the ground

By following these safety guidelines and conducting regular safety assessments, the risk of accidents and injuries can be significantly reduced. It is also essential to maintain accurate records of scaffold inspections and repairs to ensure compliance with relevant regulations and standards.

Remember, safety is everyone’s responsibility, and by working together, we can create a safer working environment for all.

| Inspection Item | Frequency |

|---|---|

| Visual inspection of scaffold tower | Daily |

| Check of guardrails, mid-rails, and toe boards | Weekly |

| Inspection of tower’s components | Monthly |

Essential Components and Structural Integrity

When it comes to scaffold towers, ensuring the structural integrity is crucial for safety protocols and preventing accidents. The first step in achieving this is to erect the tower following a safe method of work, either using an advance guard rail system or the ‘through-the-trap’ (3T) method. This method helps to prevent falls and ensures the tower’s stability.

A well-structured scaffold tower should have critical load-bearing elements, such as sturdy frames and secure foundations. Safety measures like bracing and stabilisation requirements are also essential to prevent the tower from collapsing or toppling over. Additionally, platform security features, such as guardrails and toe boards, should be in place to prevent falls and ensure the safety of workers.

By following these safety protocols and implementing effective safety measures, we can significantly reduce the risk of accidents and ensure a safe working environment. Regular inspections and maintenance are also crucial to identify potential hazards and take corrective action before they escalate into major incidents.

All LEWIS Industrial Scaffold Towers Come With a Manual and Safety Checklist

Download This PDF Example

Safe Assembly and Dismantling Protocols

Ensuring the safe assembly and dismantling of scaffold towers is crucial to prevent accidents and injuries. A workplace safety inspection should be conducted before assembly to identify potential hazards. According to the National Access and Scaffolding Confederation (NASC) Safety Guidance SG4, scaffolds must be erected, dismantled, and altered in a safe manner to prevent falls.

A safety audit should be performed to ensure that all safety protocols are in place. This includes checking the scaffold’s design and configuration, as well as the competence of the scaffolders. The NASC provides detailed guidance on preventing falls in scaffolding operations, emphasising the importance of proper configuration and regular inspections.

Some key considerations for safe assembly and dismantling protocols include:

- Ensuring that all scaffolders are competent and trained

- Conducting regular inspections to identify potential hazards

- Following established safety guidelines and protocols

- Using proper equipment and tools

By following these protocols and conducting regular workplace safety inspections and safety audits, the risk of accidents and injuries can be significantly reduced. It is essential to prioritise safety in scaffolding operations to protect workers and prevent unnecessary risks.

Regular inspections and audits can help identify potential hazards and prevent accidents. By prioritising safety and following established protocols, scaffolding operations can be conducted safely and efficiently.

| Inspection Frequency | Purpose |

|---|---|

| Weekly | To identify potential hazards and prevent accidents |

| After incidents | To assess damage and ensure scaffold safety |

| Before first use | To ensure scaffold is properly configured and safe |

Weather Considerations and Environmental Safety Measures

When working with scaffold towers, it is essential to consider the weather conditions and environmental safety measures to ensure a safe working environment. This includes assessing the ground conditions to ensure they can support the weight of the scaffold and any loads likely to be placed on it.

In strong winds, scaffold towers should not be used, as they can be unstable and pose a risk to workers. Wind speed limitations should be taken into account when deciding whether to use a scaffold tower. Additionally, adverse weather procedures should be in place to ensure workers know what to do in case of bad weather.

Ground condition assessment is also crucial to ensure the scaffold tower is stable and secure. This includes checking for any uneven or soft ground that could cause the scaffold to collapse. By taking these safety measures and following compliance guidelines, workers can ensure a safe working environment and prevent accidents.

Some key considerations for weather conditions and environmental safety measures include:

- Assessing ground conditions to ensure they can support the weight of the scaffold and any loads

- Checking wind speed limitations to ensure the scaffold tower is stable

- Having adverse weather procedures in place to ensure worker safety

Personal Protective Equipment Requirements

When working with scaffold towers, it is essential to follow strict safety guidelines to prevent accidents and ensure a safe working environment. A thorough safety assessment should be conducted to identify potential hazards and determine the necessary personal protective equipment (PPE). The UK PPE at work regulations were amended in 2022 and you can check them here.

Some of the most common PPE items used in industrial environments include hard hats, safety goggles, and fall protection gear. It is crucial to use these items correctly and regularly inspect them for damage or wear. A safety assessment should be conducted regularly to ensure that all necessary PPE is available and in good condition. By following these safety guidelines and conducting regular safety assessments, workers can minimize the risk of injury and ensure a safe working environment.

Additionally, workers should be aware of the importance of proper PPE maintenance and inspection. This includes regularly checking PPE for damage or wear and reporting any issues to their supervisor. By prioritizing PPE maintenance and inspection, workers can help prevent accidents and ensure a safe working environment. Regular safety assessments and adherence to safety guidelines are crucial in preventing workplace injuries and ensuring compliance with OSHA regulations.

Regular Maintenance and Inspection Schedule

Regular maintenance and inspection of scaffold towers are crucial for ensuring the safety of workers and preventing accidents. According to the PUWER regulation 6, equipment must be inspected after installation and before first use, as well as after reassembly at a new site or location. This highlights the importance of safety protocols in maintaining the integrity of scaffold towers.

A well-structured maintenance schedule should include daily and weekly tasks, such as checking electric cable condition, functional tests of brakes and lights on mobile machinery, and inspecting safety device functionality. These tasks are essential safety measures that help identify potential issues before they become serious problems.

- Daily inspections of scaffold tower components, such as ladders and safety harnesses

- Weekly checks of tyre pressures and conditions of windows and mirrors on mobile plants

- Monthly examinations of critical load-bearing elements and bracing and stabilisation requirements

By following a regular maintenance and inspection schedule, and implementing effective safety protocols and safety measures, scaffold tower owners and operators can help prevent accidents, reduce downtime, and ensure compliance with regulatory standards.

Emergency Response and Safety Procedures

In the event of an emergency, it is crucial to have safety procedures in place to ensure the well-being of everyone involved. This includes having a plan for emergency evacuation, incident reporting, and first aid considerations. According to the Management of Health and Safety at Work Regulations 1999, employers are required to have safety measures in place to prepare for potential emergencies.

A key aspect of emergency response is having a clear plan for evacuation. This includes identifying escape routes, ensuring that exit doors and gates are unlocked and unobstructed, and designating a safe meeting point for staff after evacuation. It is also essential to consider the needs of vulnerable populations, such as individuals with disabilities, and provide adequate assistance during evacuations.

Regular training and realistic practice are essential for effective emergency response. Employers should implement training sessions at least bi-annually for all employees, covering topics such as emergency evacuation procedures, incident reporting, and first aid. By having a well-planned emergency response and safety procedures in place, employers can minimize the risk of injury or harm to their employees and ensure a safe working environment.

Conclusion: Ensuring Ongoing Scaffold Tower Safety

Maintaining the safety of industrial scaffold towers is a continuous process that requires vigilance and adherence to best practices. Regular safety audits and compliance with established safety guidelines are crucial for protecting workers and ensuring the structural integrity of these vital construction tools.

As highlighted throughout this article, a comprehensive approach to scaffold tower safety involves meticulous pre-use inspections, proper assembly and dismantling protocols, and consistent maintenance. Employers must ensure that their workforce is adequately trained on safety procedures and that all necessary personal protective equipment is provided and utilised.

By prioritising safety at every stage, construction companies can mitigate the risks associated with scaffold tower use and create a work environment where employees can thrive. With a steadfast commitment to safety, scaffold towers can be leveraged as essential tools for successful and incident-free projects.

All LEWIS Industrial Scaffold Towers are made to last in our own foundry. All towers are certified by the BSI to the latest standard EN1004. Each manual includes a safety checklist.

FAQ

Why are safety checklists important for industrial scaffold towers?

Safety checklists are crucial for industrial scaffold towers to ensure worker safety and prevent accidents. They help identify potential hazards, ensure compliance with legal requirements, and establish a consistent process for inspecting and maintaining the scaffold towers.

What are the key components of scaffold tower safety?

The key components of scaffold tower safety include understanding the legal requirements, conducting thorough risk assessments, and ensuring the structural integrity of the tower, including critical load-bearing elements, bracing, and platform security features.

What should be included in a pre-use safety checklist for scaffold towers?

A pre-use safety checklist for scaffold towers should include inspecting the overall condition of the tower, checking the stability and security of the platform, ensuring the proper installation of bracing and stabilisation components, and verifying the availability of necessary personal protective equipment.

Why is it important to consider weather conditions and environmental safety measures when using scaffold towers?

Considering weather conditions and environmental safety measures is crucial when using scaffold towers, as factors such as wind speed, adverse weather, and ground conditions can significantly impact the stability and safety of the tower. Appropriate precautions must be taken to mitigate these risks.

What personal protective equipment is required for workers using scaffold towers?

Workers using scaffold towers must be equipped with the necessary personal protective equipment, including hard hats, safety harnesses, protective footwear, and any other equipment required to ensure their safety while working at height.

How often should scaffold towers be inspected and maintained?

Scaffold towers should be subject to regular inspections and maintenance, including daily checks and weekly maintenance tasks. Proper documentation of these activities is essential to ensure compliance and worker safety.

What emergency response and safety procedures should be in place for scaffold tower use?

Emergency response and safety procedures for scaffold tower use should include an evacuation protocol, incident reporting guidelines, and first aid considerations to ensure the safety of workers in the event of an accident or emergency.